|

+Plastic Part Design workshop

.: a Symposium for Product Designers

and Mechanical Engineers :.

Course Duration:

16 hour workshop

(This two day class is offered each month so check the design engine class

schedule for exact dates.)

Tuition: $1000.00 US

Overview: The course material is designed

to provide a working knowledge of the plastics industry thru intelligent

discussions and lectures. The bulk of your time in this workshop will

be spent on the part design requirements imposed on the designer by the

injection molding process.

Prerequisites: General knowledge of Pro/ENGINEER

another 3dimensional CAD modeler helpful but not necessary.

Call to ask for a proposal to sign up your company into a week long on-site

cumulative workshop that encompasses all three manufacturing processes

classes design engine offeres. In this way participants can master and

leverage advanced modeling techniques with specific manufacturing processes

that makes for lighter, stronger parts with confidence. These classes

can be offered anytime requiring only two to make a class in our Chicago

office. 312.226.8339

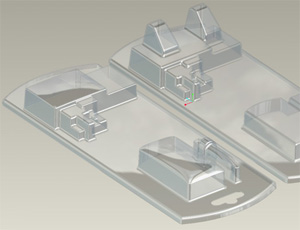

In

this exercise the participants will utilize shrinkwrap to create clamshell

parts for packaging. In

this exercise the participants will utilize shrinkwrap to create clamshell

parts for packaging.

Topics:

- The process, injection molds, vacuum formed, tooling, processing factors,

Nominal Walls, Radii and draft angles, Ribs, Weldlines, stress, cooling

plastics, bosses, undercuts,

- Discuss use of Snap fit, FEA, Design recommendations, flow mold analysis

software.

- Learn to Design injection molded undercuts

- Learn about various plastics and their material characteristics

- Engineers will learn to utilize tooling and injection molders as a resource

to design better parts.

- Learn about the metal mold itself and many of its intricacies such as

sleeve ejection, how it is cooled, sprue and runner, ejector bars, ejector

plats, and ejector pins.

Discussions:

- History of plastics

- How an injection mold functions in detail. Include mold fill short shots

and cooling.

- How China plays a major role in injection molding. Discuss the quotation

process for tooling and discuss partnering with local injection molders

vs. outsourcing. Discuss strengths and weakness of outsourcing.

- Discuss basic design elements in plastic part design. Holes, ribs, thin

wall features, bosses, nominal wall, and fill.

Discuss general rules for hollow boss design and discuss best practices.

Learn about thin steel or thin blade areas and discuss ways to avoid.

Discuss gating and discuss problems such as fill vent and eject issues

as related to. Also discuss how to design in solutions to would be cosmetic

problems.

- Glass filled and co-injection process and discuss problems associated.

Discuss ways to add structural integrity to glass filled parts by aligning

glass filler.

Discuss sink marks and discuss how to avoid using relations in parametric

software

- Cooling time as related to thick sections of plastic. Discuss internal

voids and fundamentals of other problems that occur from improper piece

part design.

- Using parametric modelers in general and discuss examples where using

variables with a parametric modeler can save problems in the future with

examples in your favorite parametric modeler.

- Discuss FEA and stress associated with plastic piece part design with

respect to FEA. Keeping in mind the deliverable for FEA is simply to make

design recommendations discuss the possible solutions to many of the common

molding problems. Keep in mind shrink, stress from sharp corners as related

to cavity filling.

- List plastic vendors and discuss their role and how designers can leverage

their experience.

Discuss the Society of Plastics engineers and their significance in the

industry

- Discuss tooling and different materials for mold design. Discuss from

a machining point of view and compare to cutting graphite for electrode

burning of steel.

- How to improve flow of the plastic through the mold and discuss Flow

Molding analysis software

- Designing undercuts and discuss advantages and disadvantages as relative

to costs

- General disclaimers on drawings such as "brake all sharp corners".

- Different types of undercuts and side pull options (can be customized

if prearranged with CAD manager of your various company)

- Discuss what challenges (flow, cooling, ejection, handling, maintenance)

a mold designer faces when designing a mold and briefly describe in detail

using your favorite parametric software an example for creating the cavity

and splitting apart the mold base

- Draft as related to surface texture kits. Discuss how to call out textures

on your favorite drawing program with examples.

- List 10 different plastics discuss their material characteristics

- Learn about relativly new plastics processes such as gas assist.

co-injected

Santoprine with polycarabonate buttons, lightpipe and brass PEM inserts co-injected

Santoprine with polycarabonate buttons, lightpipe and brass PEM inserts

Discussions with respect to Pro/ENGINEER:

- Draft in it's many forms complete with examples of split draft etc.

- Light use surfacing and its use with plastic part design.

Discuss top down design with examples.

- Adding draft to parts that currently have no draft.

Discuss making parts moldable that others created.

- Tips tricks and techniques for starting and completing plastic parts

using Pro/ENGINEER.

- Learn to use parameters to drive geometry relative to nominal wall thickness.

- B-Side geometry creation techniques including PEM inserts, bosses and

ribs.

- Utilize Draft check correctly

Participants will be able to leverage password protected HTML training

materials for later use after this workshop.

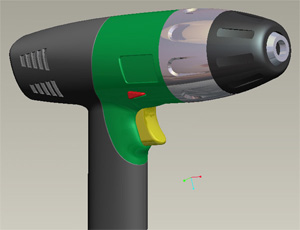

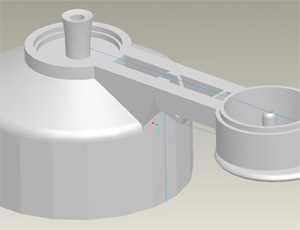

These

Pro/E parts do not currently have draft on them. In this exercises the

participants will are required to add draft onto these parts making each

part moldable. In the end participants will utilize draft check to make

sure of moldability. These

Pro/E parts do not currently have draft on them. In this exercises the

participants will are required to add draft onto these parts making each

part moldable. In the end participants will utilize draft check to make

sure of moldability.

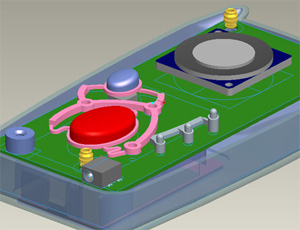

In

this exercises the participants will be required to utilize top down design

to locate hole locations for bosses and buttons making the assembly easy

to modify. Move a hole location and the boss and hole both move in all

parts together. In

this exercises the participants will be required to utilize top down design

to locate hole locations for bosses and buttons making the assembly easy

to modify. Move a hole location and the boss and hole both move in all

parts together.

Compare:

- Compare plastic injection process to die casting

In

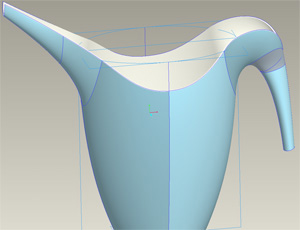

this exercises the participants will modify a curves and surfacing model

so there is a positive pull with respect to a specific pull direction.

Currently this model is not moldable with a single pull mold. In

this exercises the participants will modify a curves and surfacing model

so there is a positive pull with respect to a specific pull direction.

Currently this model is not moldable with a single pull mold.

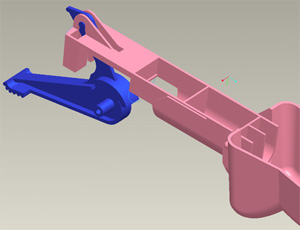

After

discussing live hinges in some detail participants in this course will

look at suggestions for specific materials and modify or create a live

hinge that will meet spec sheets supplied. After

discussing live hinges in some detail participants in this course will

look at suggestions for specific materials and modify or create a live

hinge that will meet spec sheets supplied.

|